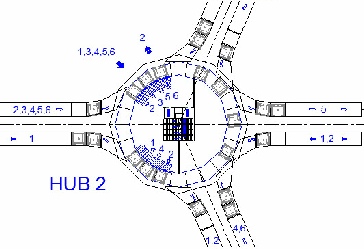

Hub Design

A hub is designed and operates like a traffic roundabout. Carries constantly enter the circle, load/unload passengers and then leave the circle to the next link. As in all detachable ropeways, there is a section where the carriers are accelerated to or decelerated from rope speed to the controlled speed within the terminal using LSM .

Each terminal has two load/unload areas. The actual size of the passenger waiting area is small compared to traditional modes of transport. Since passengers are not allowed access to the loading area until within a minute of their arriving carrier, there is only enough room for a quick loading of passengers. Unloading passengers move quickly from the carrier at their destination hub and down the escalator. With a 15 passenger size cabin and a 6 second interval the traffic flow is 150 unloading passengers per minute or 9000 passengers per hour at maximum capacity from each ropeway. If all loaded carriers were unloading in Hub 2 (to right) there would be 36,000 passenger unloading every hour or 600 passengers per hour.

The space not used for passenger loading/unloading is used for a central monitoring station for security personnel, escalators and elevators for handicap access.

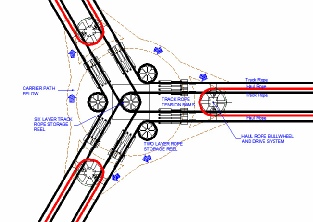

The APM utilizes a new type of ropeway design that is currently referred to as 3S. In this design there are five different ropes for each link (4 track ropes and 1 haul rope). The weight of the carriers is supported on two stationary track cables and the carriers are pulled along by a single hauling rope. The design of the hub takes into account this configuration by providing track rope tensioning, track rope repositioning and rope storage (bollards).

The APM terminal works well for this type of ropeway because all links intersect at a common point. This allows the track cables to be stored on common bollards. The terminal design allows for active repositioning of the track ropes on an occasional basis.

The design allows the link drive machinery to be located directly above each bullwheel. The machinery area also contains numerous backup power sources for uninterrupted operation even if the primary power is disrupted.

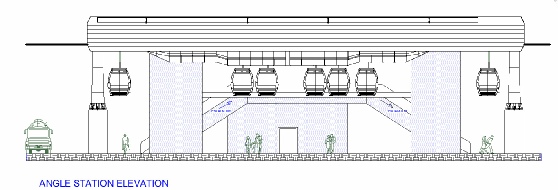

The APM terminal always loads passengers above existing grade. This design allows traffic to be controlled, reduces the footprint size and eliminates the need for hold-

The images is an example elevation for a mid-