Linear Synchronous Motor Terminal Movement

The key to the APM is the use of Linear Synchronous Motors (LSM) to control carrier movement within the terminal. In all ropeway terminals, the carrier’s movement is controlled by a series of rotating tires that press down on the friction plate mounted to the top of the grip. The rotational speed of the tires are controlled by the size of the pulley that turns the tire. The movement of each carrier is directly proportional to the speed of the haul rope and cannot be adjusted after the ropeway is installed.

Linear Synchronous Motors are simply an electric motor that has been uncoiled. Instead of producing torque, the LSM creates a linear motion along its path.

Linear Synchronous Motors are simply an electric motor that has been uncoiled. Instead of producing torque, the LSM creates a linear motion along its path.

The LSM was invented in 1840 and by 1935 the first LSM train was built. Today, almost all new high speed trains (Bullet Train in Japan) and subways are powered by LSM. The LSM now has replace the old steam catapult that launches planes from aircraft carriers.

Current computer technology allows the LSM to accurately control position and movement of pallets in automated factories for assembly and inventory placement in large automated warehouses.

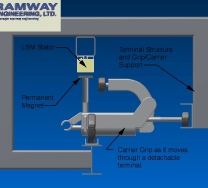

In the LSM hub terminal, the LSM is mounted directly above the carrier path. Permanent magnets are placed on the top of the carrier grip in the place of the current friction plate. Once detached from the haul rope, the LSM decelerates the carrier to a slower speed. The APM control system then control the movement of each carriers in the terminal. As an example, if the carrier is already at capacity, the carrier does not stop for passenger loading but is quickly repositioned for acceleration back to rope speed in the next link to its destination hub.

A major advantage of the LSM carrier movement technology is that there are no moving parts to install and maintain. With the exception of the transfer rails, there are no moving parts to adjust, maintain, replace and repair.